Deconstruction, re-manufacturing and reuse of facades

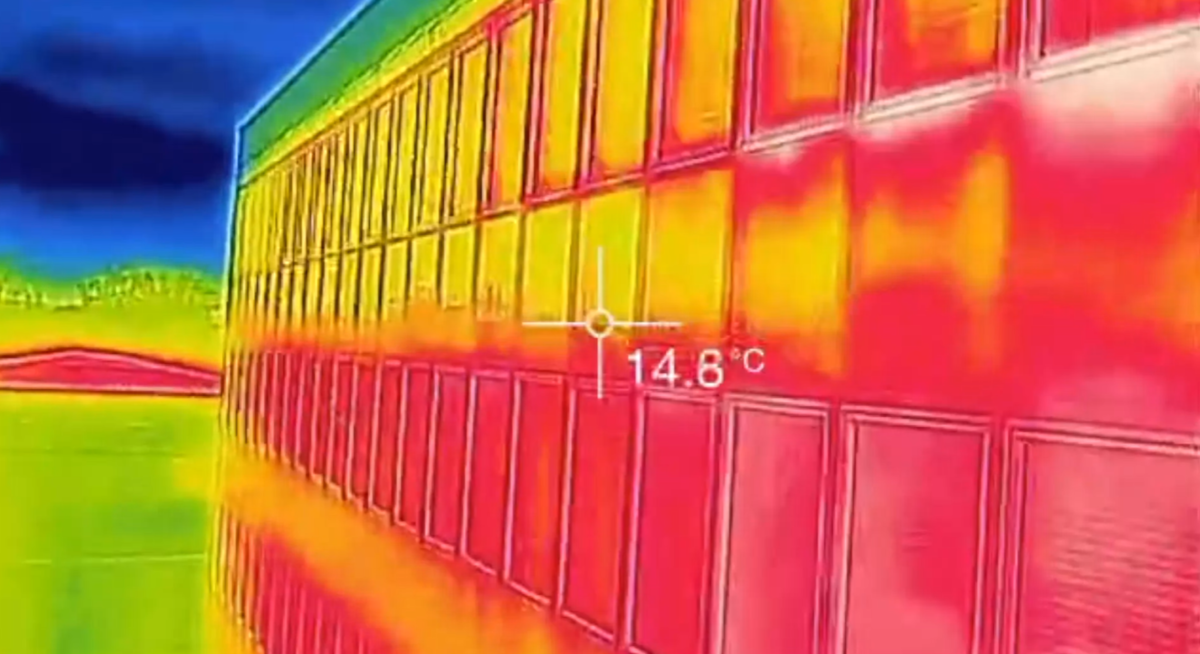

The construction of building façades lends itself to a sustainable practice not commonly employed in domestic construction. As each component of the façade is often fixed to the structure using fasteners rather than bonding agents solely, façades can be deconstructed or dismantled. Deconstructing in place of demolition allows immediate reuse of components, extending their service life and minimising the impact of the embodied carbon. With a healthy deconstruction and re-manufacturing industry, some of the previous limits on glazing service life may be negated.

This presents an interesting opportunity, as glass must be heated to 1500 ° C, and its manufacture is inherently energy intensive. However, during use, if designed well, glazed sections can save energy by reducing lighting demand and in cool climates through solar gains. So with thoughtful construction, long use and reuse, glazing elements could recoup much of their embodied carbon, making it a much more sustainable material.

Read our case study: Restoring the iconic Moor House Façade

Lifecycle assessments of the façade

The longevity of a façade, the embodied carbon of materials, and the ability to deconstruct, re-manufacture and reuse components are considered in a ‘cradle to grave’ assessment of a façade to determine its sustainability. This life cycle analysis would gauge the different impacts of the element at various stages in its use, such as energy use, pollution, and resource use, and produce a set of figures to help judge the sustainability of each material or process that constitutes the façade.

Book your Façade Condition Survey today

Novel materials for future developments

Glass has long been the only commercially viable material that allows outdoor views. But glass may find itself superseded in some applications by the process of main-streaming polymers in construction. One polymer is ETFE; a transparent polymer that is often installed in double or triple-ply pillows and is radically lighter than glass. As a further advantage, on multiple-ply pillows, intelligent fritting can be used so that user-controlled, variable shading is possible without the addition of extra equipment.

Another material group gaining traction is the composites, and though they are not yet mainstream in commercial buildings, they provide many advantages over traditional materials. Composites offer a cladding material that requires little maintenance other than cleaning, is extremely lightweight, does not act as a thermal bridge or encourage condensation, and as a result achieves a long service life.

An example of well-designed composite cladding is that of Mondial House in London. Mondial House was clad in Glass Reinforced Plastic in 1975, providing good thermal retention and protection of the building structure, and upon demolition in 2006, was still in very good condition. More manufacturers are beginning to offer Fibre Reinforced Plastics as a cladding material, largely justified by its reduced cost, and this may provide the boost needed to increase the market penetration of composites in façades.

A significant problem with cement is the emission of CO2 from essential chemical reactions during its manufacture, undermining attempts to reduce CO2 emissions by changing fuel type. Novacem – a company based on research from Imperial College London – uses different raw materials based on magnesium oxide. Novacem’s use of these materials allows a lower heating temperature, but more significantly, it takes up CO2 during manufacture, making it possible to make carbon negative cement, should it prove to work successfully when applied practically.

In a slightly different direction, two technologies present new applications for an old material. Glued Laminated Timber (Glulam) and Cross Laminated Timber laminates multiple sheets of wood to produce a much stronger building material. Glulam laminates multiple rectangular sheets to form strong, lightweight beams that can be used in place of steel beams. CLT laminates multiple sheets, each perpendicular to the next, to create strong panels suitable for use as load-bearing walls, floors and ceilings.

Get in touch to discuss your next project.